Anti-blue light screen protectors are becoming increasingly popular in global markets, especially among users who spend long hours in front of smartphones, tablets, and laptops.

However, many distributors, wholesalers, and private-label brands still ask:

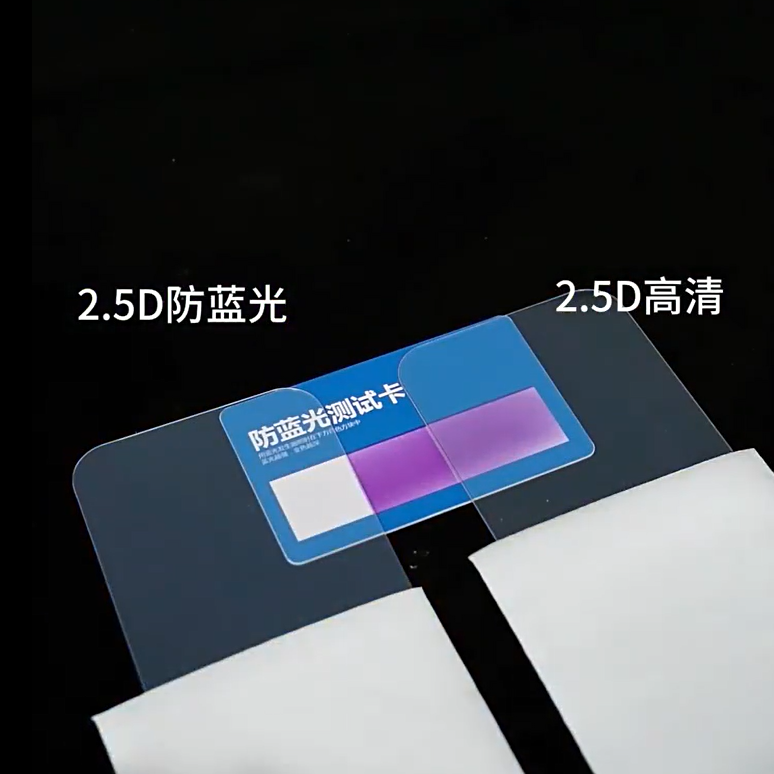

Why is an anti-blue light screen protector blue or yellowish, while a standard HD screen protector looks completely clear?

This article explains the technical reason, different anti-blue light technologies, and regional market preferences, helping B2B buyers choose the right solution for wholesale and OEM projects.

What Is Blue Light and Why Does It Matter?

Blue light mainly exists in the 400–450 nm wavelength range and is emitted by smartphone, tablet, and computer screens. Long-term exposure may cause:

- Eye fatigue

- Visual discomfort

- Reduced sleep quality

That’s why anti-blue light screen protectors are designed to filter or reduce blue light before it reaches the eyes.

Why Does an Anti-Blue Light Screen Protector Look Blue?

The blue or light yellow tint is a functional result of blue light filtering technology, not a quality issue.

To block blue light, a screen protector must either:

- Absorb blue light, or

- Reflect blue light

Both methods change how light passes through the glass, making the protector appear blue, yellowish, or warm-toned under certain lighting conditions.

Main Anti-Blue Light Screen Protector Technologies

From a factory and OEM perspective, there are three mainstream technical routes.

1. Anti-Blue Light Coating (Most Widely Used)

This is the most common solution for anti-blue light tempered glass screen protectors.

How it works

- Special optical coating absorbs part of the blue light spectrum

- Reduces high-energy blue light before it reaches the eyes

Appearance

- Slight blue or yellow tint

- Minimal impact on screen clarity

B2B advantages

- Stable quality

- Cost-effective

- Ideal for wholesale and private label production

Typical blue light reduction

- Around 20%–40%, depending on coating layers

2. Blue Light Reflection (Interference Layer Technology)

This method uses multi-layer optical films to reflect blue light.

How it works

- Blue light is reflected instead of absorbed

Appearance

- Blue or purple reflection at certain angles

- Higher transparency from the front view

B2B considerations

- Higher production cost

- More complex process

- Suitable for premium markets

3. Color-Tinted Glass (Low-End Solution)

Some low-cost products use blue or yellow glass substrates.

Appearance

- Strong color tint

- Noticeable color distortion

B2B risk

- High return rate

- Not suitable for EU, US, or branded positioning

Does a Bluer Screen Protector Mean Better Blue Light Blocking?

No.

A stronger blue color does not automatically mean higher blue light protection.

Professional buyers should focus on:

- Tested blue light reduction rate

- Optical performance

- Screen clarity

- Color accuracy

👉 Lab data matters more than visual color.

Market Preferences for Anti-Blue Light Screen Protectors

Understanding market expectations is essential for wholesale buyers.

Europe

- Mild tint preferred

- High transparency required

- Blue light reduction: 20%–30%

United States

- Accepts slightly stronger tint

- Emphasis on eye comfort and long screen time

Japan

- Extremely sensitive to color shift

- Prefers nearly transparent anti-blue light solutions

Emerging Markets

- More tolerant of visible tint

- Price-sensitive

- Often combined with privacy screen protectors

How to Choose the Right Anti-Blue Light Screen Protector for Wholesale

For distributors and brand owners, key factors include:

- Blue light filtering performance

- Screen clarity and color accuracy

- Coating durability

- Compatibility with OLED & fingerprint sensors

- OEM & ODM customization options

- Stable mass production capability

Conclusion: Blue Tint Is a Functional Feature

The blue appearance of an anti-blue light screen protector is a technical characteristic, not a defect.

For B2B buyers, the right question is not “Why is it blue?”

But:

“Is this anti-blue light solution suitable for my target market?”

Choosing the right technology leads to fewer returns, better user feedback, and stronger long-term sales.

📌 FAQ – Anti-Blue Light Screen Protectors

Frequently Asked Questions (FAQ)

Q1: Why is an anti-blue light screen protector blue or yellowish?

A:

An anti-blue light screen protector appears blue or slightly yellow because of the optical coating or interference layers used to filter blue light in the 400–450 nm wavelength range. This color shift is a functional characteristic, not a defect, and indicates that the screen protector is actively reducing blue light exposure.

Q2: Do anti-blue light screen protectors really work?

A:

Yes, high-quality anti-blue light screen protectors are effective. Their performance depends on the coating formulation and optical design, not just appearance. Professional-grade products typically reduce 20%–40% of harmful blue light, while maintaining high screen clarity. For wholesale buyers, lab-tested data is more reliable than visual color alone.

Q3: What is the difference between an anti-blue light screen protector and a regular HD tempered glass?

A:

A regular HD tempered glass screen protector focuses on scratch and impact protection with maximum transparency. An anti-blue light screen protector adds a blue light filtering layer, which helps reduce eye strain during long screen time, with a slight color shift depending on the technology used.

Q4: Does a stronger blue tint mean better blue light blocking?

A:

No. A stronger blue or yellow tint does not automatically indicate higher blue light protection. The actual effectiveness depends on optical wavelength targeting and coating performance. Excessive tint may reduce color accuracy without providing better eye protection.

Q5: Will anti-blue light screen protectors affect screen clarity or color accuracy?

A:

Well-designed anti-blue light tempered glass screen protectors maintain high transparency and minimal color distortion. Premium solutions are optimized to balance blue light reduction with screen clarity, making them suitable for EU, US, and Japan markets.

Q6: Are anti-blue light screen protectors compatible with fingerprint sensors and OLED displays?

A:

Yes. High-quality anti-blue light tempered glass is designed to work with OLED displays and in-display fingerprint sensors. Proper adhesive thickness and coating control ensure smooth touch sensitivity and reliable fingerprint recognition.

Q7: Which markets prefer anti-blue light screen protectors?

A:

- Europe: Prefers mild tint with high clarity

- United States: Accepts slightly stronger blue light filtering

- Japan: Requires near-transparent anti-blue light solutions

- Emerging markets: More tolerant of visible tint and price-focused

Understanding regional preferences helps distributors select the right product version.

Q8: Are anti-blue light screen protectors suitable for wholesale and OEM/ODM projects?

A:

Absolutely. Anti-blue light screen protectors are widely used in wholesale, private label, OEM, and ODM programs. Buyers can customize coating level, packaging, branding, and product positioning based on target market requirements.

Looking for Anti-Blue Light Screen Protectors for Wholesale?

Contact us for custom OEM/ODM solutions with competitive pricing and fast lead times.Get a Quote