With the continuous popularity of smartphones, the requirements for screens are getting higher and higher, but the probability of screen damage during use is also increasing, so the tempered film was born to provide security for these smartphones. Today’s smartphones continue to upgrade and innovate and need more and more tempered film protection, so their demand will never decrease because major mobile phone manufacturers will not stop the development and manufacturing of smartphones. In this blog, we will tell you that the mobile phone tempered film only need 10 steps.

Step 1: Glass Raw Material Cutting

It needs to make inspection When Glass Raw Materials Unloading, and Cut the square sheet into small pcs required size of glass by Cutting machine, and workers put them on white paper one by one and get ready for Carved processing.

Step 2. CNC Carved Process

The small pcs of glasses materials were sent to the CNC carving workshop, and the rough small material is carved according to the design drawings by the CNC machine Digital & Computing Control Panel. And It is the initial shape of the mobile phone tempered glass screen protector, but it still has some burrs on the edge of the glass, it needs to enter the next steps and make it more round.

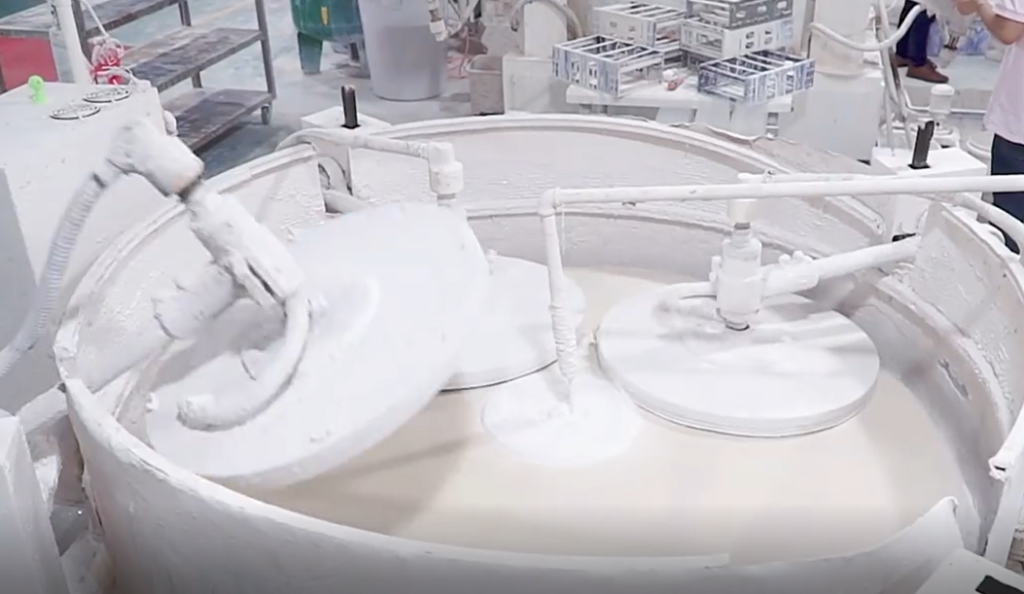

Step 3: Glass Surface Polishing Process

Put glasses on the polishing machine one by one and grind in the Flat grinding sweep light department. Glass grinding must be done on the upside of glass so glass looks attractive after Grinding. Use high-density fabric to polish the carved glass, so that the processed glass surface will be more dense, transparent, bright, and smooth, and the life will be longer. After this grinding edges of glass shine, more and will not hurt your hands easily.

Step 4: Ultrasonic Wave Clean Process

The Surface of the polished glasses is very dirty, It needs to be Clean by 11 processes through 9 cleaning tanks. It is based on the principle of ultrasound, and then there will be some grooves here, the first groove first put the glasses in the first groove, and then to the second, third, fourth, one-by-one is this Go down, and the more you wash, the clear it. everything will be cleaned.

Step 5: Tempering Process

The glass needs to be tempered after the step of clean processing and forming. It is a very important step and determines the quality of the tempered film. Workers Put the whole rack directly into the tempering furnace, and soak the semi-finished products in a special solution, with a temperature of more than 400 degrees. High temperature, long time immersion for 4~8 hours, chemical reaction of ion replacement on the white glass flakes, so that the glass out can be called rigid tempered glass, which is not only high in strength and toughness but also will not be formed sharp glass when broken. It will protect your life at any time.

Step 6: 2nd Round Ultrasonic Wave Clean Process

After Tempering Process. It still needs to clean the glass by Ultrasonic Wave Clean Process, it looks more beautiful after washing, and enter 1st QC process and find the Defective products;

Step 7: Silk Printing

Silk Printing is to make the tempered film exactly the same as the phone screen, as the part of the phone. you will not find it. Use special ink to print the edge of the tempered glass, so that it can better fit the phone. And white edges can be avoided, When the phone is been sticked by tempered film, It will be more beautiful.

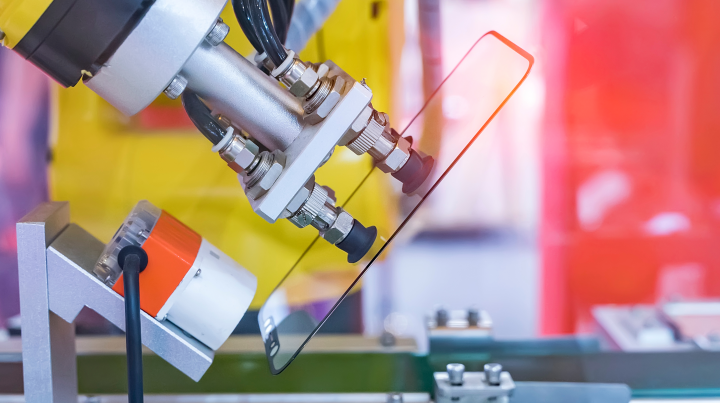

Step 8: AB Glue Process

The most important stage is here, we enter the dust-free workshop, and the toughened glass can be affixed with ab glue after screening, Workers Manually make AB Glue Process Under Dust-free working Environment. Most kind styles in the market including the familiar privacy film, blue light film, purple light film, green light film, and other color films, etc., It’s just pasted with different ab glues. So it is easy to make what you want colors.

Step 9: Oleophobic &Hydrophobic Layer Spraying By Machine

After the 2nd QC Process and control quality strictly, It will be prepared to apply fingerprint oil. A good fingerprint oil and process are also very important in this step. Generally, there are plasma spraying fingerprint oil and electroplating fingerprint oil. The process of electroplating fingerprint oil is more high-end, and the cost will increase a lot. But it will be shown that the surface of processed tempered glasses is very smooth, Drops of water will not spread out like ordinary glass and stand on the glass like a ball,the surface of the film is more resistant to stains, anti-fingerprints, and more wear-resistant.

Step 10: Final Package

Labeling Process automatically and make 3rd Round QC process, After careful quality inspection of the finished product, the finished product of the tempered film will be marked and bagged according to the sub-inspection. put them in a new package, and you have new tempered glass screen protector in your hands.

The whole production process is not complicated, but every step is very important. So when you see not only a simple tempered film and includes the quality created by professional links one by one.